What points must be met in the design of vehicle-mounted flexitanks?

Date:2023.12.01 Number:LET-NEW-193

The design of vehicle-mounted flexitank must meet four major points: safety, storage, usability, and sealing. Safety mainly refers to

the strength of the container bag. When designing, the packaging volume, weight of the contents and number of packaging units

must be considered, as well as the distance of transportation and the number of times of transportation, as well as the means of

transportation and transportation methods used. The storability should be based on the user's usage conditions, reasonable selection

of materials, and reasonable proportions. The anti-aging ability of plastic products under sunlight exposure is currently a matter of

great concern, and it is also a problem often encountered in the actual use of container bags. When designing a container bag, it is

necessary to fully consider the specific ways and methods used by customers to use the container bag, such as lifting, transportation

methods, loading material performance, etc. In addition, it is also necessary to consider whether it is food packaging and whether it is

non-toxic and harmless to the food packaged. Different sealing packaging materials have different sealing requirements. For example,

powdered materials or toxic items, or items that are afraid of being contaminated, have very strict requirements on sealing performance.

Materials that are prone to moisture or mildew also have special requirements for air tightness. Vehicle-mounted flexitanks are mainly

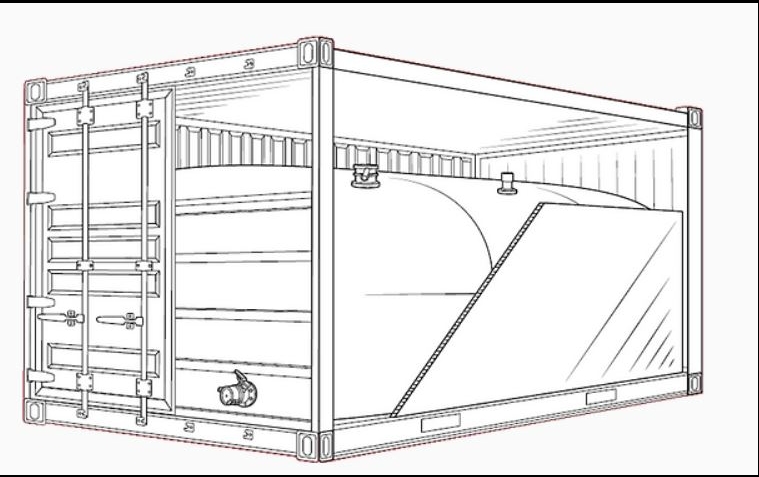

another form of container flexitanks, combined with the flexitank form used on trucks, to save packaging and transportation costs.

Vehicle-mounted flexitank:

Flexitanks used with flat guardrail trucks and heavy trucks can be customized according to customer requirements and truck size.

Vehicle-mounted flexitanks solve the problem of having to use containers when transporting flexitanks in domestic cities, reducing

customers' transportation and packaging costs.

Flexitank is a new type of liquid bulk packaging container used in combination with containers. LET container flexitanks are made of

food-grade low-density polyethylene (LDPE) and polypropylene (PP) through heat sealing and sewing processes. They have the advantages

of safety and hygiene, high operating efficiency, and saving customers' packaging costs.

Advantages of container flexitanks:

Packaging procurement cost is low. Compared with traditional liquid packaging containers, LET container flexitanks can save customers

50-80% of packaging procurement costs.

2. Reduce customers’ logistics costs. Containers using flexitanks can carry 25 cubic meters of goods, which increases container utilization by

56% compared with traditional packaging containers.

3. Health and Safety. The inner material of the flexitank is food-grade low-density polyethylene, which can directly contact food-grade

liquid products; the LET flexitank is a disposable package that does not require cleaning and is more in line with food packaging requirements.

4. High operating efficiency. It only takes 20 minutes to load and unload a container of flexitank, which is easy to operate and saves labor.

5. Strong applicability. Flexitank containers can meet the transportation requirements of railway, sea and highway.

6. Green. The container flexitank is made of degradable materials, recyclable, environmentally friendly and pollution-free.