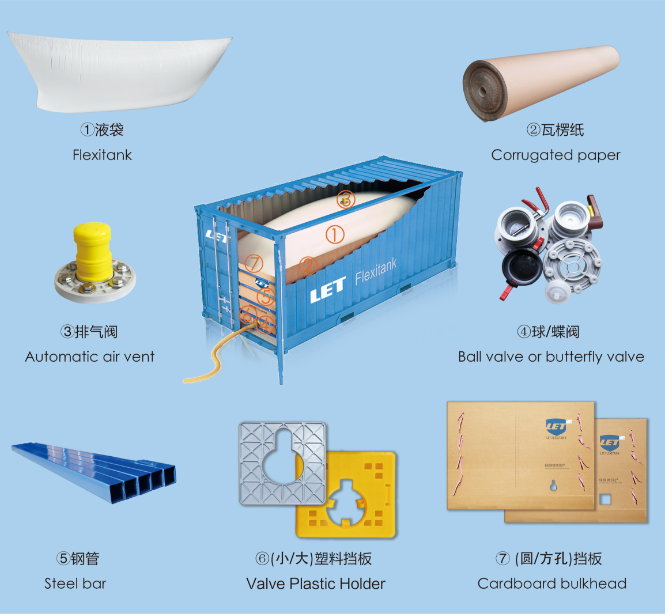

TYPES OF FLEXITANK

Date:2023.11.16 Number:LET-NEW-150

The first flexitanks marketed were reusable and needed to be cleaned before further use. Nowadays, flexitanks are single-use and made from 100% recyclable materials.

According to capacity:

Flexitanks’ capacity is expressed in litres with a density equal to 1 g/cm3, i.e. showing their maximum load capacity for products with this density such as water and wine.

A flexitank can hold between 16,000 and 26,000 litres, although the most common models can contain 18,000, 20,000, 22,000, 24,000 and 26,000 litres. We usually choose

the model with the largest capacity bearing in mind the product’s density. The recommended flexitank sizes by product type are:

Flexitank for transporting glycerine: 19,000 l and 20,000 l (depending on densities).

Flexitank for transporting wine: from 24,000 l to 26,000 l.

Flexitank for transporting oil: from 24,000 l to 26,000 l.

Flexitank for transporting latex: 24,000 l.

According to uses:

Standard: suitable for any bulk liquid not considered hazardous cargo.

With an EVOH barrier: especially used for shipping bulk wines and juices as this barrier stops oxygen getting in.

Reeflex: for goods which need to travel at temperatures below ambient temperature. Dairy products are a good example.

Aseptic: protects the cargo from contamination as it has a sterilisable aseptic loading valve. It is designed for very sensitive products such as milk and juices.

According to the number of layers:

Considering the number of layers which it is manufactured, there are three types of flexitank:

Multilayer flexitanks: they are made with 3 or 4 layers of polyethylene. The main advantage of the multilayer flexitanks is that each layer is very thin and flexible, making it very

easy when the download is complete roll the semi-empty flexitank to not leave losses.

Monolayer Flexitanks: this type of equipment is manufactured with a single layer of polyethylene thicker and thus less flexible. Its main advantage is that no product can remain

between the layers.Bilayer flexitanks: combine the advantages of the previous two systems. It is manufactured with a layer of polyethylene, hard as monolayer but thin and flexible,

laminated with a second twisted layer which protects the interior of the irregularities of the container.

According to the loading valve:

There are 3 systems of loading/ unloading in the flexitanks market:

Upload/ download above: flexitank is equipped with a valve on top of it, which means that both loading and downloading an operator must climb above the bulkhead, to connect

and disconnect the hose. While gravity loading and unloading is simpler, it is more time-consuming.

Upload/ download below: in this case the valve is located on the bottom front of the flexitank and passes through the bulkhead or bulkhead, which is simple and safe to connect the

hose to load or unload.

Dual: : allows two different products to be carried in the same container. It is often used for shipping bulk wine as it makes it possible to load two types of wine in the same flexitank with

a capacity of 11,000 and 13,000 litres